CT Cores

“These guys always have proven their supply to be of great quality and excellent speed. Great supplier all round.”

Redback Performance Radiators are made in Australia using the highest quality materials to suit a wide variety of applications.

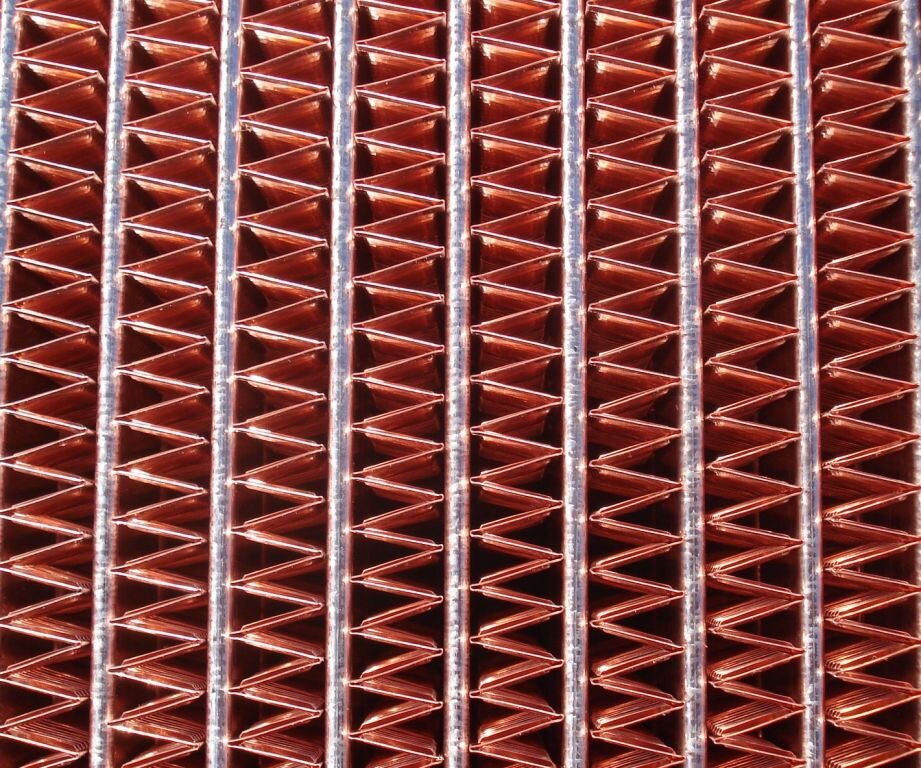

CT cores feature a 16x2mm butt welded brass tube. A High Frequency Welded joint runs the length of the tube to ensure maximum strength and service life. The superior Quality butt-welded tube is sourced from the USA and has an Industry leading tube wall thickness of 0.006”, contributing further to the premium strength of Redback Radiators CT cores. Butt welded tubes are significantly more resilient in service than the soldered lock-seam budget tube seen on many of today’s cheaper or imported copper and brass radiator cores.

High Quality copper & brass fin material is sourced from Europe to ensure accurate material properties and gauges are used for extended service life.

Cutting edge technology and wind tunnel modelling developed for motorsport cooling have lead to the optimum louver design used in the Redback 8.4 CT core. The same DNA used in F1 and NASCAR is built into every Redback CT core, ensuring the pinnacle in cooling performance is achieved, satisfying the additional heat rejection required in the latest emission controlled engines.

Redback CT cores feature a Quality hem, doubling the material gauge to the core faces.

A Quality range of Turned up, Bolt- on or Vintage styled header plates are available.

Precision Headerplate extrusions ensure a quality tube fit up and couple with Redback Radiators unique soldering techniques to form a “tuff” durable product.

CT Core Configurations:

2 Row – 38mm

3 Row – 57mm

4 Row – 76mm

5 Row – 95mm

Credits

Firstname Lastname

Title / Role

Firstname Lastname

Title / Role

Firstname Lastname

Title / Role